Use Cases

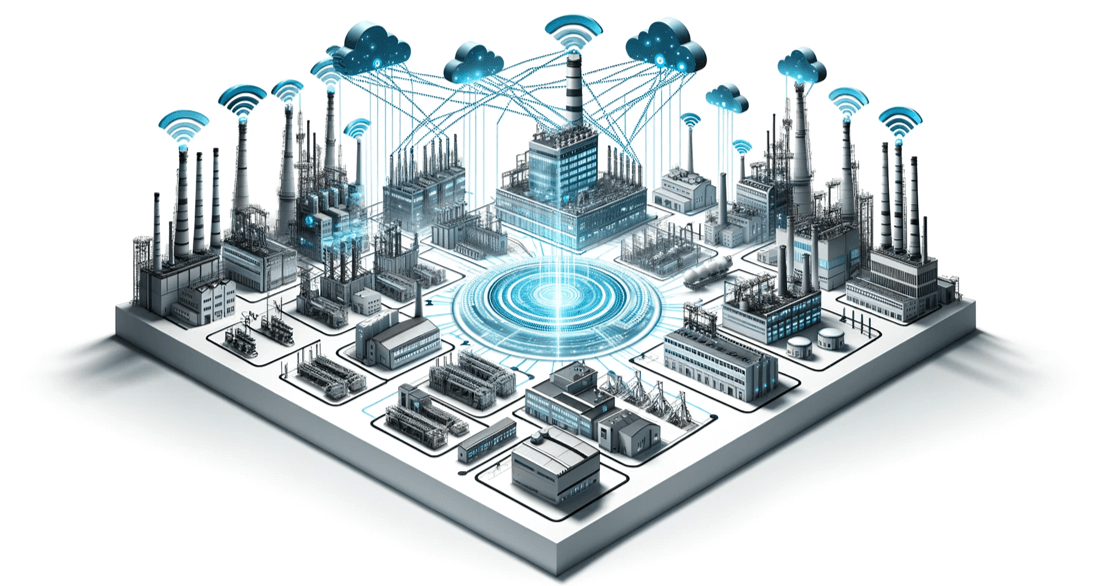

Multi-site Integration in Industry 4.0

Industry 4.0

Objective

Implement on-premise Scramjet Transform Hubs for data integration across multiple production lines, enhancing real-time data sharing and processing.

Core Components

-

Data Streamers: Facilitate real-time data flow from PLC devices.

-

Process Optimizers: Analyse and optimize production processes and stockpiles.

-

Process Orchestration: A centralised system relays the data between separate production lines to ensure just-in-time supply.

Benefits:

-

Rapid Deployment: Quick setup of Scramjet Transform Hubs on premise and immediate cloud integration.

-

Real-Time Data Sharing: Instant data exchange between PLC devices across multiple production lines.

Cost Savings:

-

Reduced Downtime: Predictive maintenance minimizes unexpected machinery failures.

-

Just-in-time supply: Prevents over and understocking, preventing downtime due to pile ups.

-

Resource Optimization: Less manual inspection, automated monitoring.

Conclusion:

Implementing Scramjet Transform Hubs in Industry 4.0 settings revolutionizes data integration and processing across production lines, yielding significant efficiency gains and cost savings. It's a strategic move towards a more connected, responsive, and efficient manufacturing environment.